DESIGNING A PLASTIC OBJECT WITH THE KNOWLEDGE OF ALL THE STEPS NECESSARY TO CREATE IT: THIS ALLOWS US TO OPTIMIZE THE COSTS OF PRODUCTION OF PLASTIC INJECTION MOLDS FROM THE FIRST MOMENT.

Csplast offers technical and aesthetic solutions for plastic products.

Thanks to our long experience PlastDesignStudio has come to life in 2012 as a branch of Csplast; it is a design studio specialized in plastic product development.

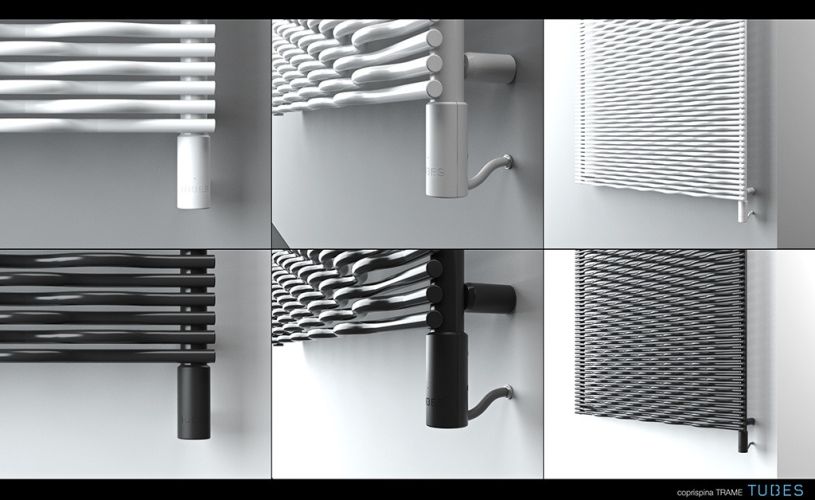

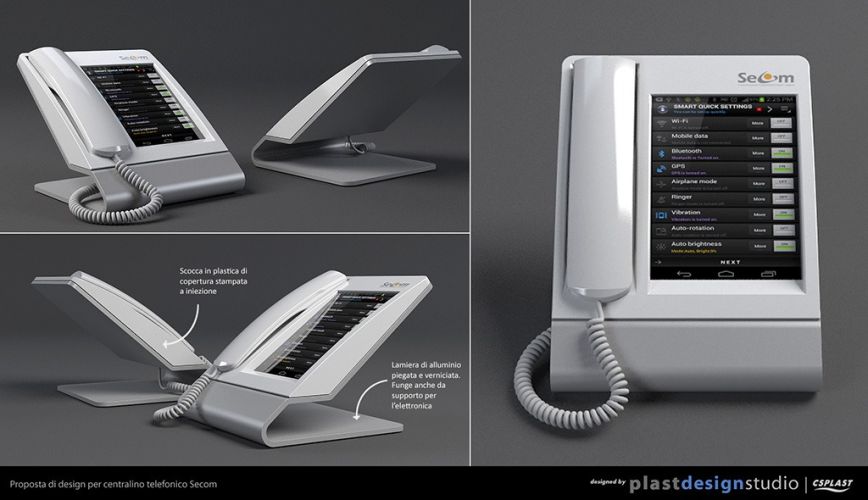

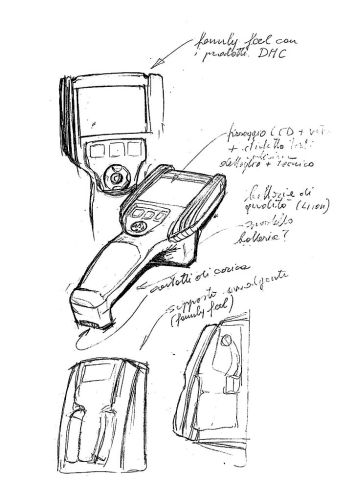

The constant collaboration with our clients enable us to offer technical and aesthetic solutions for the development of the industrial design for their plastic products. We start defining the appearance of the object (shape, details, surface finishes, colours…), but we never forget to integrate it with all the project and technical requirements needed, such as environmental, ergonomic and mechanical criteria.

Our design studio works in close contact with Csplast moulds engineering and construction department so we can always avoid those common problems linked to the redesign of parts and components that were purely based on aesthetics without knowing how they should be done in order to be produced with injection moulding or which turn out to be too expensive to be realized.

FROM THE VERY FIRST STAGES OF CONCEPT DESIGN EVERY DETAIL IS INTEGRATED WITH THE PLASTIC PRODUCT’S FUNCIONALITY VIA A CAREFUL PIECE’S ENGINEERING

SUSTAINABLE DESIGN: here in Csplast we believe that respecting the environment is an essential design feature and we are committed to creating projects with a low environmental impact.

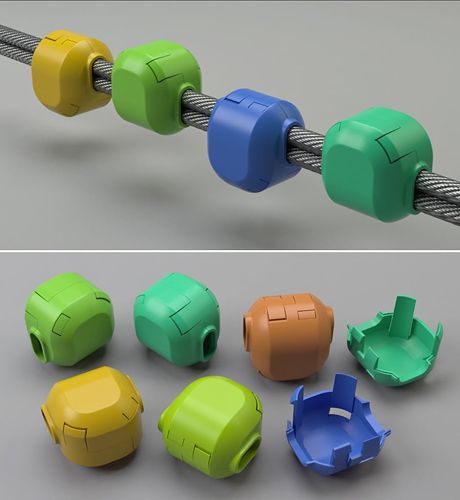

DESIGN FOR REDUCTION: to reduce the use of materials and energy throughout the product’s life cycle.

DESIGN FOR DURABILITY: to increase the maintainability and lengthen the life expectancy of the product.

DESIGN FOR DISASSEMBLING: to facilitate disassembly of the components in a product to optimize end of life cycle operations.

At the end of this first step – the industrial design phase – we provide top quality images and photorealistic renders which make it possible to see the finished product before the injection mould has even been made.

OUR DESIGN BECOMES PRODUCT