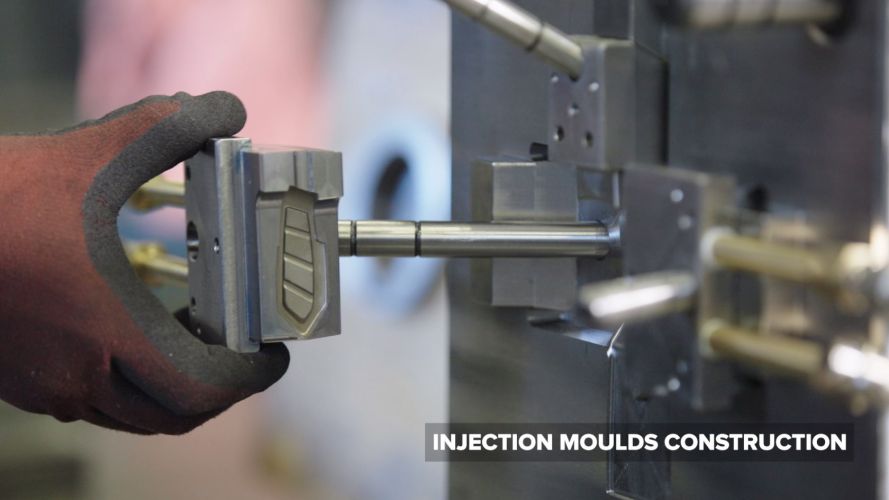

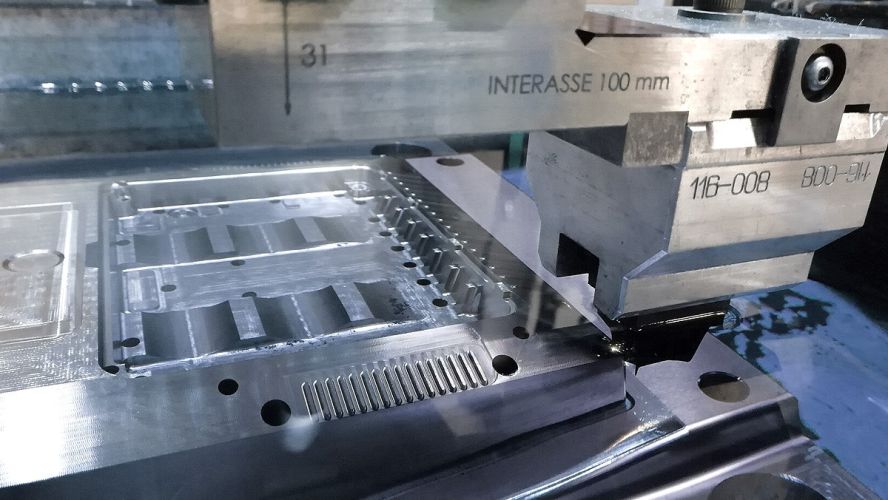

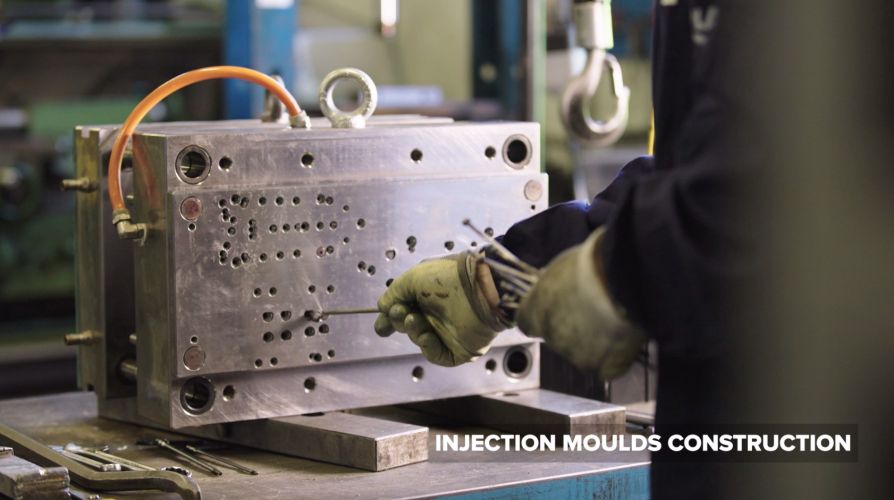

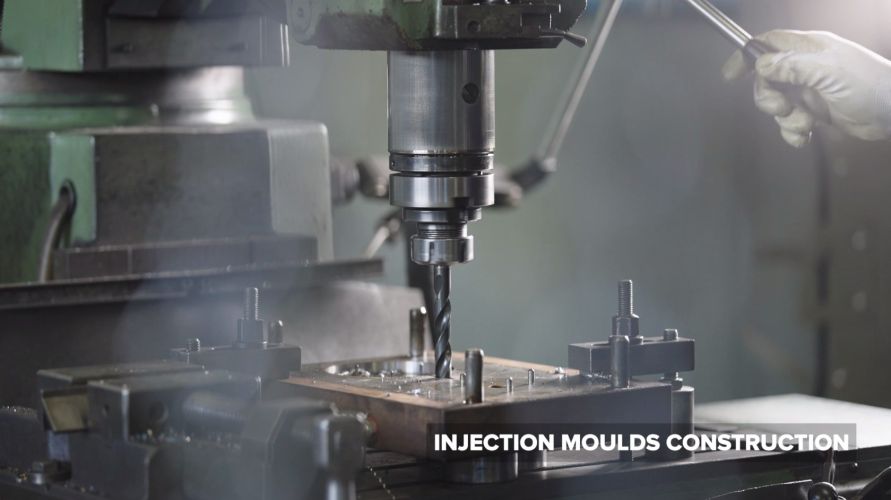

Csplast injection mould construction department uses the designing and manufacturing experience of our highly-qualified technicians and makes use of technological and up to date machines, as CNC high speed milling machines and state-of-the-art erosion machines.

Every year a lot of injection moulds are created in our department designed to many different sectors, which can be subdivided in two big areas:

– Box for electronics, where it is necessary to realize moulds for plastic shells and covering for electronics components. The main sectors for which we work are the medical one, the automation and hand-held device, the security and the industrial instrumentation one;

– Technical articles: realization of injection moulds for mechanical components, products for the vending machine sector and for the food processing equipment. In other word we work for all the field of work in which the metal-plastic conversion represents an innovative and qualitative choice.

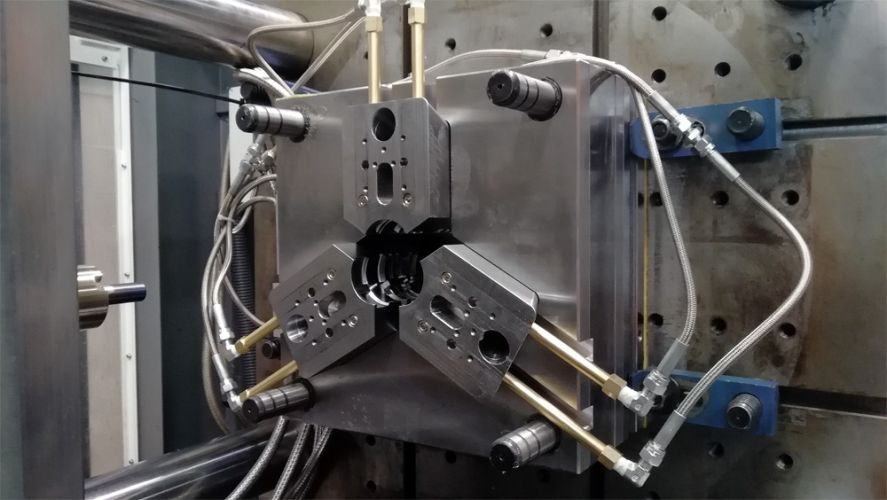

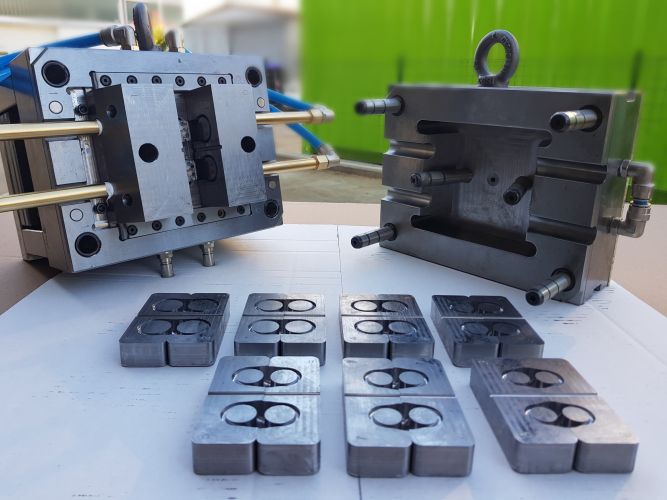

All the injection moulds are developed according to the needs of the customer, in order to obtain the best optimization for its costs and efficiency. For example, for small production batches we propose aluminum moulds or we try to simplify every possible constructive complications, whereas for high production batches we choose hardened or tempered steel moulds, multi-cavities moulds, etc.

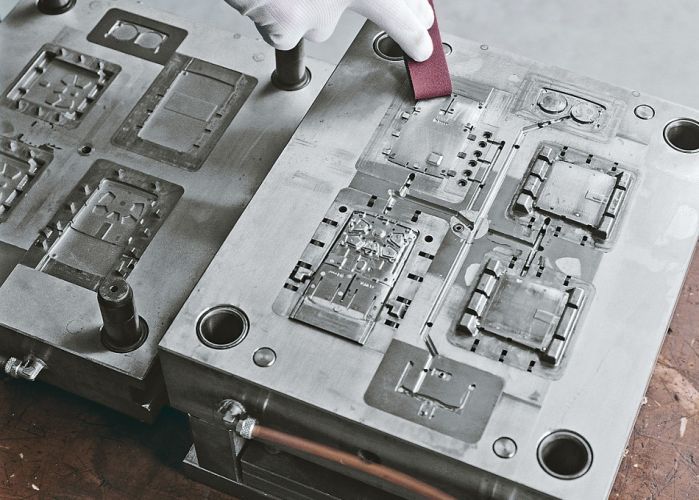

When the injection mould construction department works in close contact with the engineering and injection moulding ones, every possible disconnection in the project development is avoided. For this reason we are able to realize products which are immediatly usable and we obtain considerable savings in terms of time and money.

MAINTENANCE AND GUARANTEE OF MOULD OPERATION

The plastic injection moulds we make are the exclusive property of the customers and are kept on consignment with u,s so as to be immediately available for the injection moulding. They are carefully checked at each start and end of production, before being stored, in order to guarantee their constant optimal functioning.