For the perfect execution of shotcreting and cast-in-place operations for reinforced concrete structures, it is crucial to ensure that rebars/mesh are correctly arranged and hold their position during casting and curing. These plastic spacers for rebars and electro-welded mesh, patented and manufactured by us, make it possible to position reinforcing elements on floors or on pipes of any diameter, even for specific sizes if requested, thanks to the diversification of models and formats.

For over 40 years they have been used by major construction companies operating in numerous sectors:

- Building

- Roadbuilding

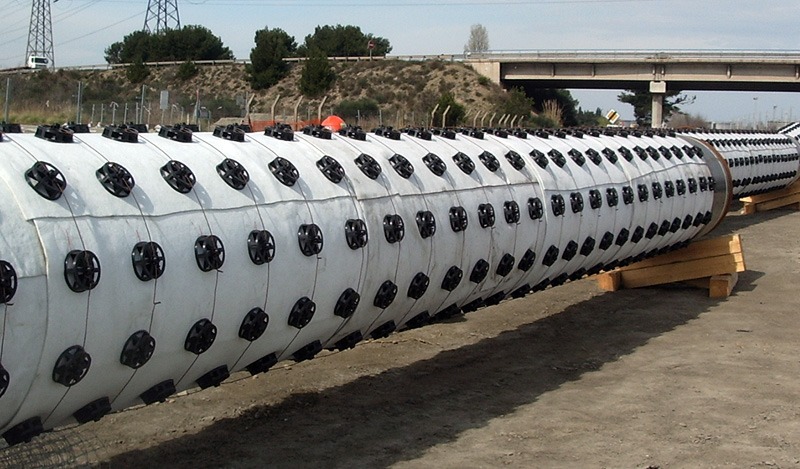

- Pipeline construction

- Offshore pipeline construction

- Flooring

LIGHTNESS, which permits:

- storage in containers which can easily be handled by a single worker, even when holding significant quantities (100-200 pieces).

- transport using relatively simple equipment.

- easy handling and streamlined assembly operations.

STRUCTURE: specifically designed to withstand large vertical loads and with openings to ensure the cement can flow through them forming an integrated structure with no gaps.

SHAPE: designed to suit any kind of metal reinforcing mesh (type A); in fact, just the mesh intersections can also be used for positioning the various sections (special system for flooring).

MODULARITY: their special shape means these spacers (type A) can be stacked on top of each other. Thanks to a special interlock that allows them to be stacked, these spacers can be used to create multiple reinforcements, even with different heights between the various layers of mesh, creating a reinforced sandwich type concrete structure of differentiated strength.

VERSATILITY: thanks to the side opening these spacers are easily attached to piping using any type of metal wire or rope, while the numerous side and top openings ensure complete incorporation into the reinforced concrete, thus keeping the structure intact and without any weak points.

ECONOMY AND QUALITY OF END STRUCTURE: the economical savings which can be achieved compared to the cost of producing cement, wooden or metal spacers should not be underestimated. The finished structure guarantees total compactness, without dangerous gaps or possible fracture lines. Furthermore, the precise positioning of the metal mesh layer, in compliance with engineer specifications, provides builders, users and testers with a better guarantee against possible undesirable disputes concerning quality, appearance and strength of the flooring.

MATERIALS: our line of reinforcing mesh spacers is made from two types of plastic, depending on customer needs:

- UV-stabilized polyamide for the most demanding uses, especially at temperatures of >60°

- UV-stabilized polyamide for standard and winter use