THE CHALLENGE

Ducale snc, a long-established company that started out manufacturing professional bar machines and then expanded its business to include totally automatic coffee making machines, today represents a reference point for the automatic distribution, vending and horeca sector.

The company, which has patented a number of its products, is constantly looking for new answers to the needs for innovation requested by the market, such as the construction of more compact machines which are easier to maintain and with better electronics.

This propensity towards innovation led Ducale to turn to the Csplast team to redesign certain mechanisms which are fundamental to the operation of their machines:

- The cup dispenser system: originally made from sheet metal. To achieve the end result the sheet metal underwent several processes, such as bending, welding, painting and assembling with screws.

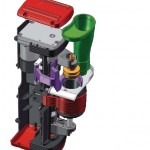

- Automatic coffee brewing unit: initially built using machine tool technology and made up of a brass boiler. Movement was achieved by means of mechanical cams.

All the aforementioned processes led to very high production times and costs to achieve the end piece, which is why the company came to use to redesign the parts in plastic and optimize them for mould injection.

THE SOLUTION

Engineering

Csplast’s objectives were clear from the offset: converting and redesigning the parts made from sheet metal to plastic so as to optimize production and simplify assembly.

To achieve optimum conversion of these mechanisms, made up of several elements closely linked to one another, our engineers used structural FEM analysis aimed at simulating the functioning of all the individual components and the final assembly in standard operating conditions. In this way it was possible to check the correct redesign in plastic of the mechanisms, having excluded any possible critical aspects of operation caused by piece deformation or fragility. Furthermore, to achieve even more satisfactory optimization, a shape was studied which would facilitate cleaning and improve maintenance operations.

Our in-depth knowledge of polymers allowed us to identify the best materials for the injection moulding process and to design parts based on this choice: for those parts which required a low friction coefficient and durability over time, POM and TEFLON were selected; for those parts which had to be self-extinguishing we selected ABS AE V0; for components which need a high mechanical resistance we used PA FV; for food-contact parts we selected atoxic, FDA certified PC; some components were made in PPS due to its very high stability and long-term thermal resistance to temperatures of up to 200°C.

Prototypes

Once the executive 3D mathematics had been created for the various components we decided to make a series of nylon prototypes using sintering technology.

This made it possible for the client to check the interlocking of the various parts which make up the mechanisms, not only between the components themselves but also between the components and the machine in which they were to be installed, as well as to check mechanical resistance.

Injection mould engineering and injection moulding

Once the prototypes had been validated, PlastDesigStudio, in collaboration with Csplast, engineered and made the injection moulds designed for the production and industrialization of the new plastic mechanisms.

RESULT

With the cup dispenser system the conversion from metal to plastic made it possible to optimize and speed up the assembly of the components by using interlocking parts and therefore to simplify maintenance procedures. Furthermore, the use of plastic made it possible to significantly reduce the weight of the machine and the noise emitted during operation. The product also proved to be more eco-friendly thanks to the absence of paints and the total recyclable nature of the plastic parts. On the other hand, for the automatic brewing unit the switch to technopolymers made it possible to significantly reduce the number of parts and therefore accelerate assembly times. This translated into a significant reduction in production costs with improved product quality and operation.

All these elements can therefore be summarized in:

- increases in the efficiency and sturdiness of the parts;

- lower maintenance costs;

- improved aesthetics and a company image in keeping with the times;

- less impact on the environment.

- CUP DISPENSER – ENGINEERING

- CUP DISPENSER – Injection moulded and aseembled piece

- ORIGINAL METAL CUP DISPENSER

- AUTOMATIC UNIT FOR COFFEE BREWER ENGINEERING

- AUTOMATIC UNIT FOR COFFEE BREWER – Injection moulded and aseembled piece