Our plastic moulding Department employs high tech injection presses, which produces plastic elements originally realized with other material. This is possible thanks to the steel moulds, which are engineered and built in Csplast.

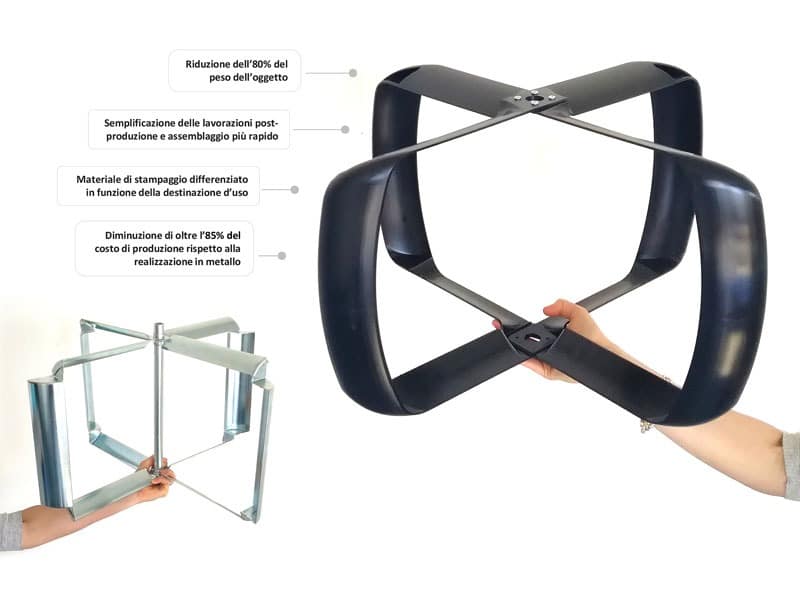

Just like this fan for air mixers, which was originally made of folded, welded and galvanized sheet metal. This production method involved high costs and required numerous balancing operations due to the imprecise nature of the processing.

Every step of the industrialization process that lead to the series production of the new plastic fan were carried out by Csplast:

- re-design of the product aimed at obtaining producibility through injection moulding;

- mould design and mould construction;

- moulding of the new fan.

In Csplast every injection mould is realized on the customer’s production needs, optimizing efficiency and costs. The design and manufacturing experience of our technicians allows our re-design from metal to plastic to bring several benefits:

- Production cost reduced by more than 85% compared to the metallic one;

- Elimination of balancing operations, thanks to injection molding which allows to obtain pieces that are always identical in shape, weight and size;

- Weight reduced by 81%, very important because the product is mounted on the ceiling;

- Differentiation of the plastic material according to the application and intended use: resistance to aggressive fumes, resistance to high temperatures of use, arrangement in more or less humid environments, etc;

- Ease of assembly;

- Improved aesthetics;

For us it is not just about production, but about coordination and perfect integration of the different phases from the project to the mass production, the customer protection and the attention to details. We can guarantee a fast and safe project development and a considerable saving of time and costs for our customers, thanks to our flexible structure; our mold construction workshop works in close contact with both the engineering dept. and the plastic molding production department.