Csplast has been offering a design and construction service for injection moulds and plastic product moulding for over thirty years.

But what is an injection mould? When was this technique for moulding plastics first used? What are the benefits and advantages of injection moulded products?

With this article we want to give you a number of details and general notions on this type of technology, providing you with even more means for understanding and making the most of our services. More specifically, we will be taking a closer look at the following aspects:

- 1. A brief history of injection moulding

- 2. What is plastic injection moulding?

- 3. How injection moulding works – the injection moulding press

- 4. The advantages of injection moulding

A brief history of injection moulding

In 1868, John Wesley Hyatt and his brother Isaiah were the first to inject hot celluloid into a mould and in 1872 they went on to patent one of the first plunger injection moulding machines.

The process remained much the same until 1946 when James Hendry built the first injection moulding press with a dual-function screw, thus revolutionizing the plastics industry.

Today, approximately 95% of moulding machines use dual-function screws to efficiently heat, mix and inject the plastic into moulds.

What is plastic injection moulding?

The injection moulding process is a production technique that makes it possible to create plastic parts. Plastic, in the form of small granules, is brought up to melting point creating a liquid mass which is then injected under pressure into the cavities of the mould. Once the plastic has reached and filled the cavities, it cools down and solidifies in the shape of the cavities. The part thus obtained is the end product.

The injection moulding technique can be used to create innumerous items, from the smallest, such as the tiny stoppers for perfume sample bottles or cogs for automatic production lines, up to large items such as the panels on automatic vending machines or furniture such as chairs and sofas.

With this technology it is possible to produce consumer goods, which tend to require a technologically simpler profile, as well as parts for high-tech industrial sectors where more sophisticated levels of performance and greater dimensional accuracy are often needed.

The thermoplastics most commonly used in injection moulding are polystyrene, ABS, polyamides and polypropylene, however for a more in-depth look into this aspect, see our Table of Raw Materials in the Download section where you will also find more detailed information on technopolymers and their characteristics.

How injection moulding works – the injection moulding press

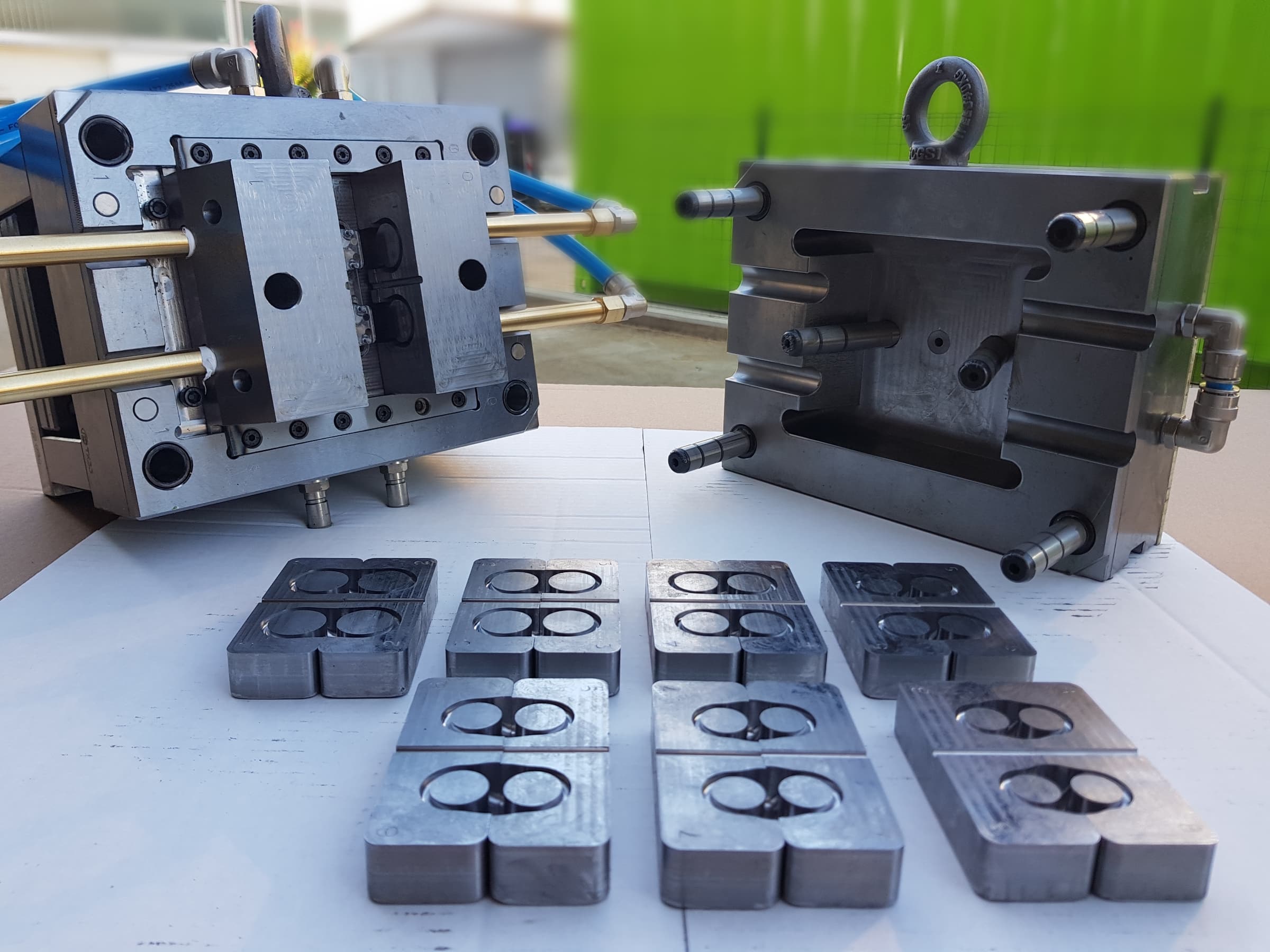

Injection moulding is a process requiring the use of different equipment and machinery. First of all, as already mentioned in the points above, a mould made up of two parts or mould halves (core and cavity) must be designed and made. When molten plastic is injected into the cavities, the shape of the component being made is formed

But where is the mould installed?

Lo The mould is positioned on a machine known as an injection press, in turn made up of an injection unit and the part on which the mould is installed (clamping unit).

The injection unit on the press is designed to melt the thermoplastic polymer and then inject it into the mould via the movement of the plasticizing screw.

The molten plastic thus arrives in the clamping unit where a mould has already been installed and where, once the plastic has solidified, thanks to a specially designed ejector system, the finished product is obtained.

This entire process is supported by a control system which constantly regulates and monitors the operating pressure, speed and time of each production step. Each individual parameter is set by our process technicians who, thanks to their experience in this sector, are able to best setup injection presses to achieve the optimal and efficient moulding of parts in compliance with technical, dimensional and aesthetic specifications.

The advantages of injection moulding

Now we come to the main advantages injection moulding can provide to those who opt to use this technology for their projects:

- • high levels of production efficiency are possible as moulding cycles are fast and accurate;

- • the higher the quantities, the lower the unit cost, consequently this technology is very often used for mass production;

- • highly repeatable moulding process, in other words identical products can be produced over and over again in compliance with part tolerances;

- • wide range of thermoplastics, colours and aesthetic finishes to choose from;

- • high level of injection moulding process automation, making low production waste achievable, a feature not to be underestimated when seeking to respect and protect our ecosystem;

- • the capacity to create large and small products with extreme precision and attention to detail;

- • after moulding no reworking or post production work is required as injection moulding can produce finished products.

To summarize, thanks to its consolidated experience in the injection moulding sector, Csplast can support you in the design and creation of your plastic items, offering an extremely customizable service which is attentive to your every need.

For any further information or queries, don’t hesitate to contact us.